What is industrial automation?

What is industrial automation?

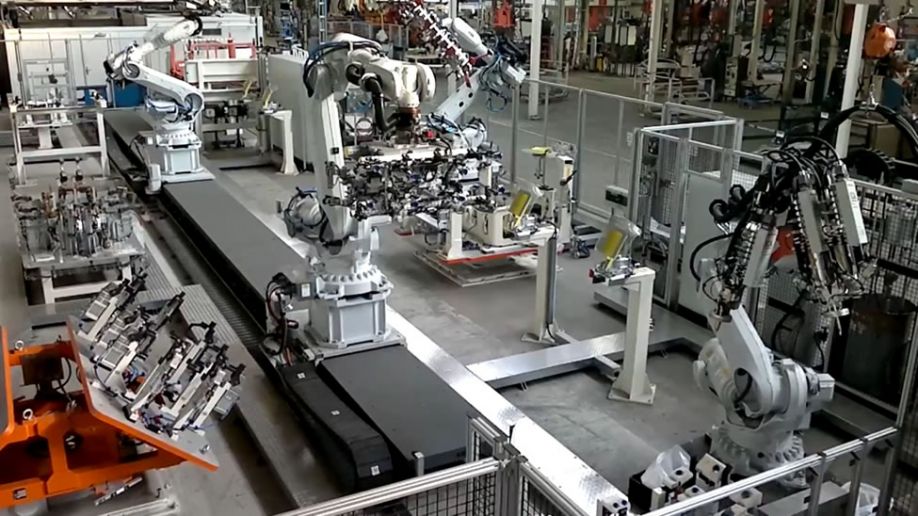

Industrial automation is the use of control systems, such as computers or robots, and information technologies to manage different processes and machinery in an industry, aiming to optimize its processes and increase production. It is the next step beyond mechanization in the realm of industrialization.

Industrial automation enhances quality and flexibility in its manufacturing process.

Previously, the purpose of automation was to increase productivity (as automated systems can operate 24 hours a day) and reduce costs associated with human operators (i.e., wages and benefits). However, nowadays, the focus of automation has shifted towards enhancing quality and flexibility in the manufacturing process. In the automotive industry, for example, installing pistons in the engine used to be done manually with an error rate of 1-1.5%. Currently, this task is performed by automated machinery with an error rate of 0.00001%.

Optimal Operating Costs

The integration of various processes in the industry with automated machinery minimizes cycle times and effort, thus reducing the need for labor. Therefore, investment in employees is saved with automation.

High Precision Information

Adding automated data collection can allow you to gather key production information, improve data accuracy, and reduce data collection costs. This provides you with the facts to make the right decisions when it comes to reducing waste and improving your processes.

Increased Safety

Industrial automation can make the production line safe for employees by implementing robots to handle hazardous conditions.

Conclusion

Industrial automation has recently found increasing acceptance across various industries due to its immense benefits such as increased productivity, quality, and safety at low costs.